GEARS

Gears Documentation Blog Entry

In this page, I will describe:

The definition of gear module, pitch circular diameter and the relationship between gear module, pitch circular diameter and number of teeth.

The relationship between gear ratio (speed ratio) and output speed, between gear ratio and torque for a pair of gears.

How I can design a better hand-squeezed fan, including the sketches

How my practical team arranged the gears provided in the practical to raise the water bottle, consisting of:

Calculation of the gear ratio (speed ratio)

The photo of the actual gear layout.

Calculation of the number of revolutions required to rotate the crank handle.

The video of the turning of the gears to lift the water bottle.

My Learning reflection on the gears activities.

These are the definition of gear module, pitch circular diameter and the relationship between gear module, pitch circular diameter and number of teeth:

Gear Module: This refers to the size of the gear teeth.

Pitch Circular Diameter: This is the imaginary circle that passes through the contact point between two meshing gears.

Relationship:

Below is the relationship between gear ratio (speed ratio) and output speed for a pair of gears.

When gear ratio increases, the torque will increase and the output speed will decrease.

Vice Versa, when the gear ratio decreases, Torque decreases and output speed increases.

Below is the relationship between gear ratio and torque for a pair of gears.

Below are the proposed design to make the hand-squeezed fan better:

I would change the knob of the piece used to connect the handle to be in the shape of screw with treading so that I can tighten it with a nut. This is because when we were trying out the fan because the knob was just simply slide in with nothing to secure it, it keep sliding up and out of place. This cause the entire alignment to be skewered which meant that it was harder for us to push the handle in for the fan blade to spin.

Pictures taken of initial design of fan

Sketch:

Below are the description on how my practical team arranged the gears provided in the practical to raise the water bottle.

Calculation of the gear ratio (speed ratio).

Gear Ratio:

Speed Ratio = 1/Gear Ratio = 1/26.67 = 0.0375

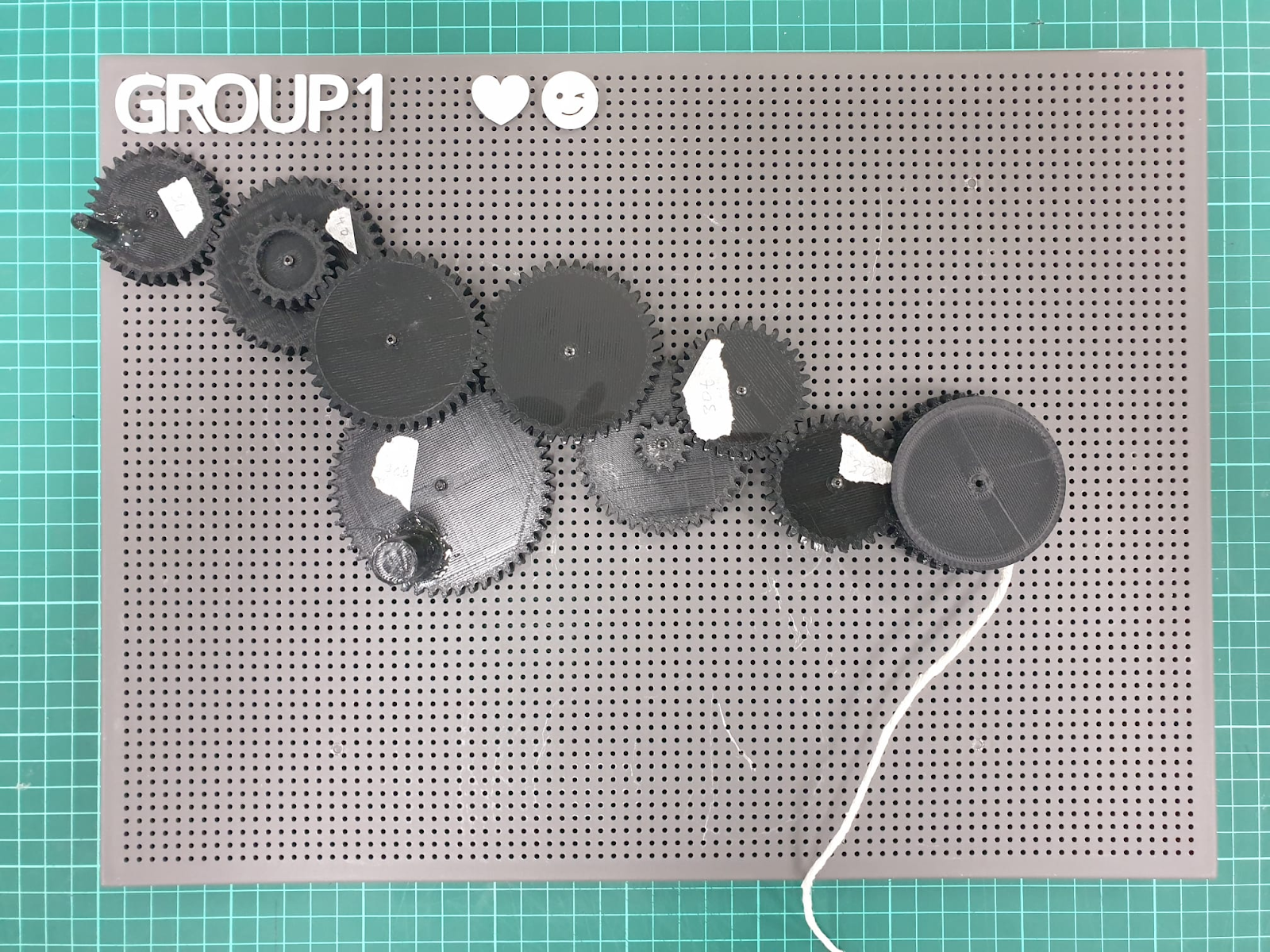

The photo of the actual gear layout.

Calculation of the number of revolutions required to rotate the crank handle.

The video of the turning of the gears to lift the water bottle.

Below is my Learning Reflection on the gears activities

Today was quite fun. We get to let our imagination run wild to design the placement that we wanted the gears to be in order to lift a water bottle. We were quite successful in the end as we gotten the highest gear ratio of 26.67 compared to the other groups!😊 However, there were of course some hiccups along the way where the first try we did not included all the gears given to us so we had to do again. This took some time as we had to figure out how to rearrange it again to get the highest possible gear ratio. But we did manage in the end as you can see from the top.😉

Next we get to assemble a fan that was 3D printed. This took quite some time because when we assembled it we couldn't get the fan to spin. When we check the inside of the fan we realized that some gears was not touching each other. We tried a different set and it still did not work. We had to get another group set and surprisingly it worked! However, we still wanted to get to the bottom of why our set did not not work. It was only 30 minutes later that we realize we make a mistake in the arrangement. We actually swapped the placement of 2 gears. It was really a moment " A Ha, I got it." moment for me when we figure that out. After we swapped the gears back the fan blade worked smoothly. I would call that a success of this activity.

Overall, it was a fun and enriching experience where I get to learn so many new things that previously i have never known before.🐣

Comments

Post a Comment